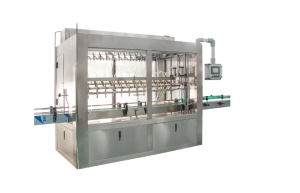

Volume Filters made in volume of the volume

One of the most significant benefits of a volumetric piston filler is its accuracy in dispensing precise amounts of product. Using a piston and cylinder mechanism, this filler sucks in and dispenses the product with very high accuracy The piston moves back to allow a preset quantity of liquid in and then pushes the product out into container. This process can be accurately regulated across volumes from a few milliliters to many liters and typically has an accuracy range in the region of +/- 0.5%. Applications that demand a precise amount in terms of dosages or product volume are pharmaceuticals, food production, and specialty chemicals.

Consistent Among Production Lots

As such, the reliable use of a volumetric piston filler makes certain that every container contains the exact same quantity of product, regardless of the batch. This consistency not only eliminates the variations that can occur with other types of filling machines in response to changes in product viscosity or other environmental conditions. A Volumetric piston filler on the other hand is able to keep the same fill volume despite slight changes in product properties, such that weight and volume of the product will be approximately the same without continual adjustments. This is particularly useful in ensuring brand consistency and customer satisfaction.

Ideal for High Viscous Products

Volumetric piston fillers are great for heavy, stout products that are hard to handle on other fillers. Starting from gels, creams and then pastes and thick sauces, you needs a filler that can handle the density of such product without clogging or material inconsistency. A positive displacement force is created by the piston in these fillers, allowing even the thickest of materials to move smoothly and efficiently into the designated containers. This enables fast, clean filling of product into your product stream there by minimising wastage and increasing production speeds.

It can easily accommodate containers of many sizes

A major benefit to volumetric piston fillers is the capability to customize each unit to work with complimentary container sizes, without losing a high level of fill accuracy. Able to handle a broad range of container volumes, the machine can be adjusted to accommodate the distance the piston travels. Because of their ability to accommodate large and variable fill volumes, piston filling machines are perfect for facilities that create multiple product lines, as the fillers can be easily adjusted to different size packages with little downtime between product runs.

Reduced Product Waste

Additionally, it delivers such efficient control over the amount of product that it helps reduce product waste. The volumetric piston filler fills each container ensuring practically no underfill or overfill situations that may jeopardize product loss or cost, respectively. This upgraded accuracy not just constructs it more charge proficient, but helps with sustainability because less waste is developed while headroom phase production.

Investing in a volumetric piston filler is investing in precision and speed. Not only does this technology help maintain a high level of quality but it also improves production outputs and return on investment. Ideal for high-throughput, accuracy-based filling, our piston fillers are built for realities where your operations demand value in product consistency.